Lost shelf life

Produce harvested from the same field on the same day can vary dramatically when it comes to retail shelf life. Ambient temperature, time of harvest, distance to cooler and cooling time all play a part.

Lack of control

Produce temperature and travel time are typically not monitored. Coolers are loaded and un-loaded based on produce arrival time, ignoring the impact of residual field heat.

Maximize shelf life by prioritizing produce

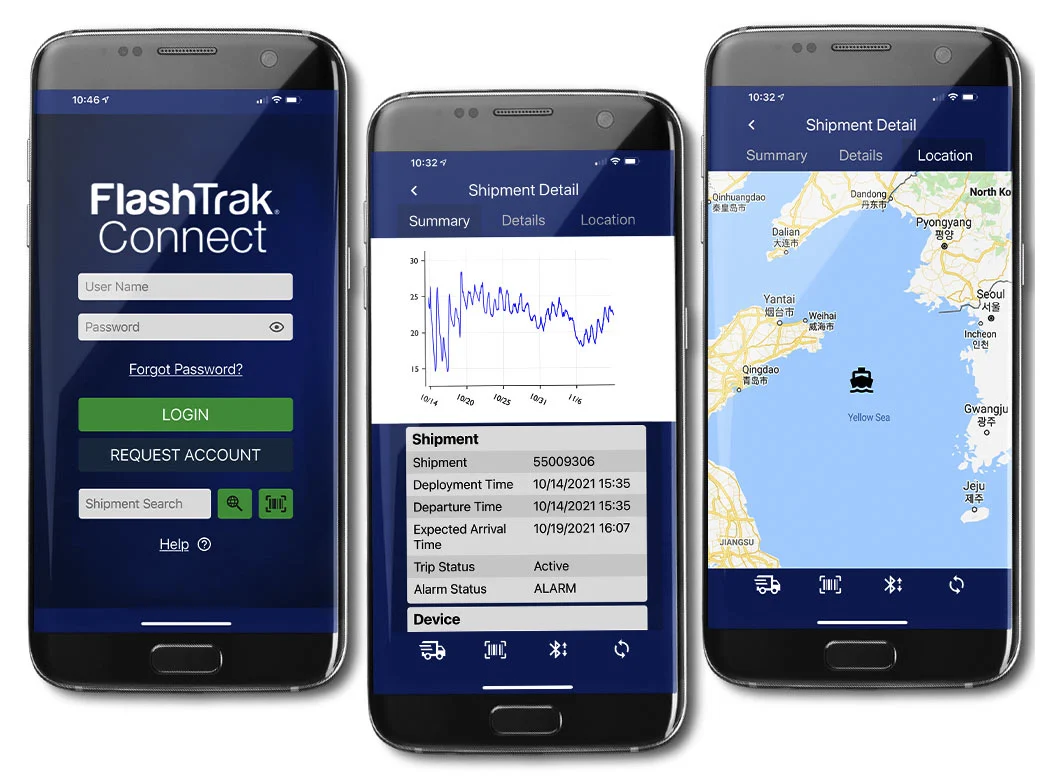

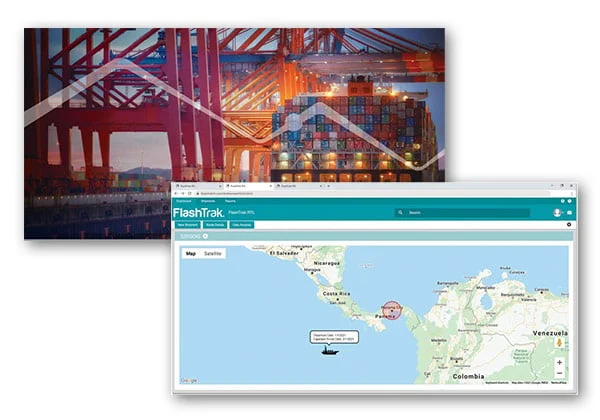

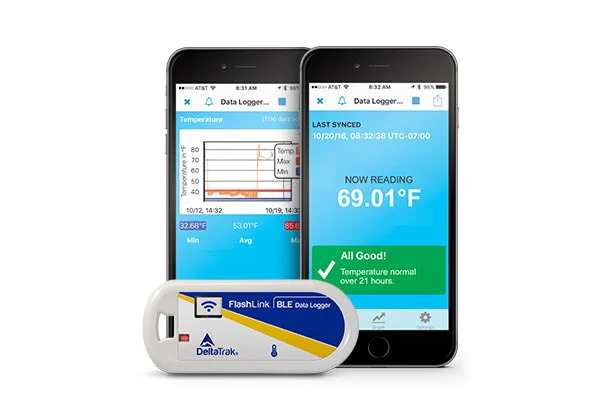

DeltaTrak solutions help prioritize based on temperature not timing, enabling shelf life to be optimized for heat and humidity-sensitive products and reducing wastage in the process.