October 24 2022

The following article was written by Yasu Kurauchi, Director DeltaTrak Japan, for Teikoku News Daily

Our company is importing and selling a variety of temperature monitoring equipment from DeltaTrak, headquartered in California, USA

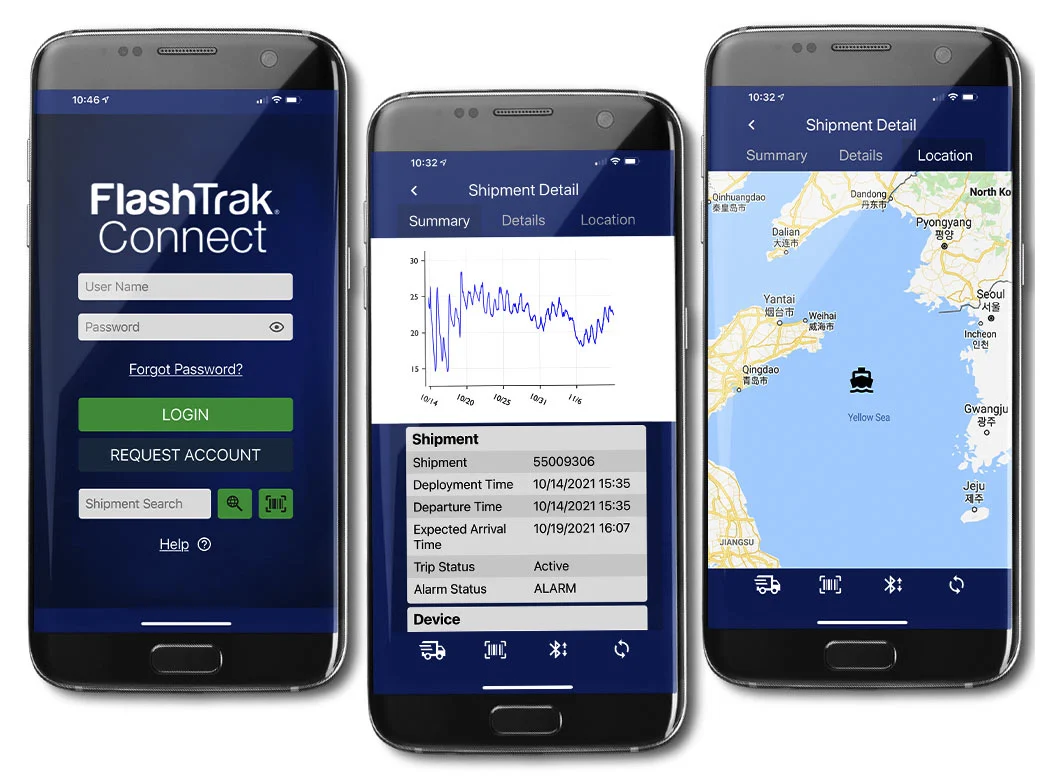

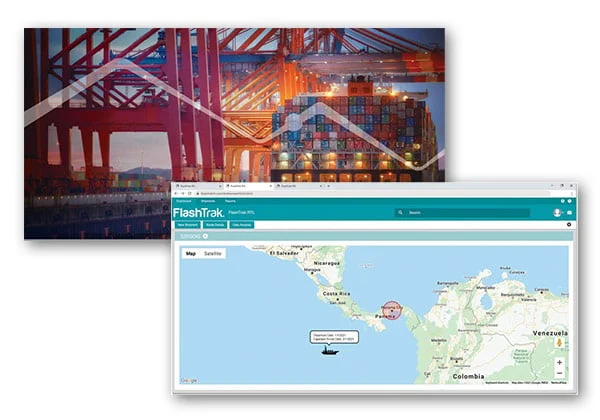

There are a variety of products including thermometers and similar tools which are used in commercial kitchens and for any cooking application, but the main products are temperature data loggers and chart recorders for monitoring the environmental temperature changes of commodity storage and transport.

When exposed over a predetermined time to inappropriate temperatures, condition of products such as pharmaceuticals, seafood, fresh fruits, vegetables, and frozen food, are known to degrade, thereby compromising function and quality. Plastics and chemicals used in semiconductor fabrication, and high-tech materials used in the aviation and space industry are also very sensitive to temperature change.

Including the adoption of packing materials that can retain temperature for storage and transportation, it has been a wide range of efforts to achieve cold chain management, but temperature monitoring instruments are the most popular supportive device to monitor and record the temperature change.

By the way, with regards to the design specifications of these instruments, those are designed a different in ways of thinking, since the driving distance per delivery in the States of America is much longer than Japan that is even smaller than the State of California.

There is no difference in the consideration for the basic aspects both in Japan and USA in terms of collateral of temperature measurement accuracy and anti-tamper mechanism, but westerner prefers disposable type which is identified as suitable for use with long-distance transportation.

On the other hand, there is in the manifestation of the “Mottainai” spirit, Japanese prefers a reusable type which is based on the premise that the instruments can be used repeatedly and apply downward pressure on higher cost of the instruments.

If it is repeatedly used over a long period of time, periodic re-calibration is required. It is also typical for some products to require re-calibration service, if in fact that is sent back to the United States, there was no economic practicality. Strategy was adopted in these was the provision of “tailor-made (custom according to individual needs) services”.

By adding our own calibration and custom configuration services to the basic specifications of the United States, we are able to make the products Japanese user-oriented.

Although there is a big change from the import company business scope, for the president who has experience as a development engineer in major chemical companies, it was not so difficult a decision.

The big decision was that “it is not to be just a copy of a local version of the calibration services that is being done in the United States, but it is to be ISO17025 accredited calibration services.” And as a result of focusing on market trends in pharmaceutical industry, we decided that “we must ensure the accuracy of the temperature monitoring equipment more strictly.”

It took less than two years since its conception, including the preparation period, such as recruitment and employment, education and training of technical staff, but was a planned ISO17025 accredited calibration businesses. Calibration technicians issue a calibration certificate with the accreditation symbol. Calibration results are not only traceable to national and international standards, but also as a calibration service provider we also prove we have sufficient technical competence.

Aside from existing customers who had been waiting for the certification acquisition, inquiries and contracts concluded by new customers have also increased