Supply Chain Transparency/Visibility

Knowing the complete history of a food product empowers every participant in the supply chain to respond to a government inquiry at a moment’s notice.

Reduced Waste and Sustainability Improvements

FlashTrak’s real-time IoT monitoring helps prevent food loss and the resulting environmental impact from methane emissions.

Product Quality in the Supply Chain

Using real-time track and trace sensors along with advanced methodologies such as Alpha Numeric Quality Code (ANQC) helps extend produce shelf-life and protect profits.

FlashTrak Chain of Custody

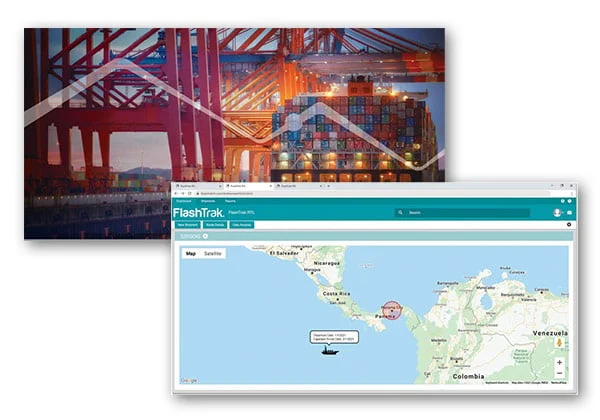

FlashTrak Chain of Custody is a complete supply chain management solution which helps you restore focus to your core business by monitoring your supply chain for you.Chain of custody (CoC) expands FlashTrak’s functionality, to indicate the real-time custodian of your product, determine product quality and confirm compliance with government regulations. Detailed product traceability identifies each party that took possession of the product along the supply chain, where, when, how much and for how long.

Utilizing Electronic Data Capture (EDI) and Application Program Interface (API), FlashTrak Chain of Custody provides users with whole chain visibility, improved cold chain management, support for government compliance, and the power to take quick, deliberate action during a foodborne illness event. By aggregating transactional data contributed by stakeholders, users, and 3rd party providers along the supply chain (Consortium Partners), FlashTrak CoC provides complete traceability and insights regarding product quality.

Benefits of FlashTrak Chain of Custody

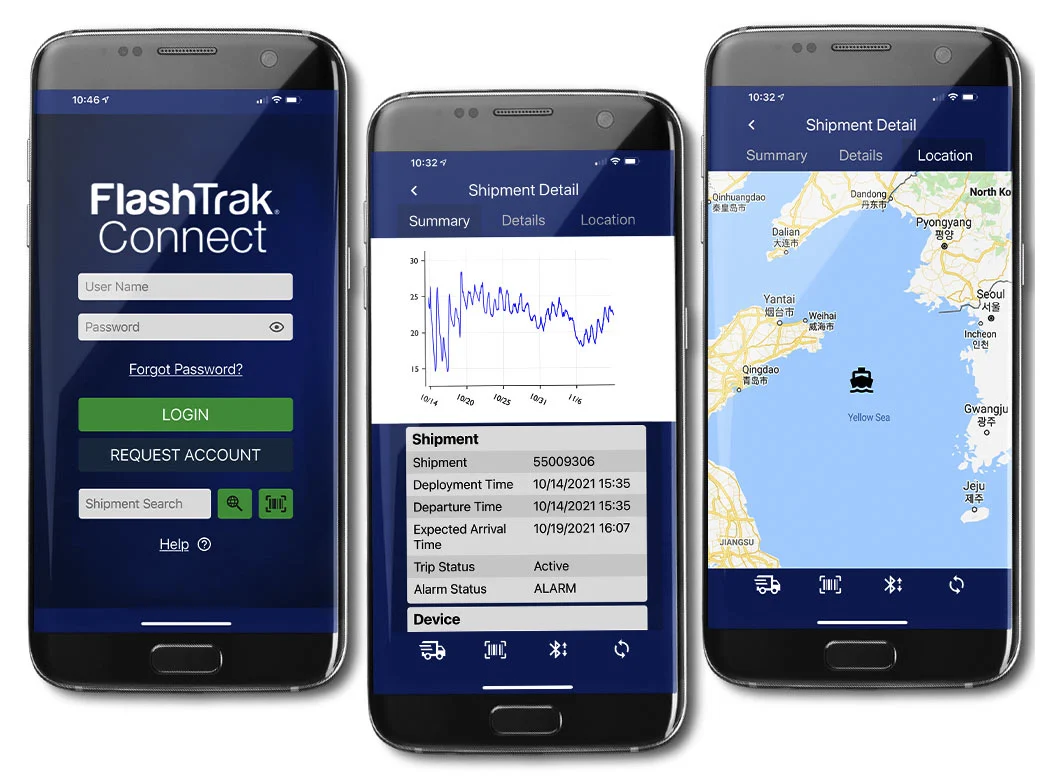

FlashTrak Chain of Custody integrates FlashLink real-time IoT monitoring to give up-to-the-minute location and estimated arrival times (ETA). By monitoring and recording temperature, humidity, light exposure, and shock throughout the entire shipment, FlashTrak also helps to determine shipment condition and identify possible security breaches (light sensor). Real-time IoT track and trace gives our customers the advantage of preventing losses of cargo and profits.

FlashTrak Chain of Custody was designed to utilize data captured by Electronic Data Interchange (EDI) and Application Programming Interfaces (API). The system also incorporates key data from various sources to build a complete understanding and provide detailed information regarding critical tracking events. Instead of using bill of ladings, container numbers or vehicle tracking, FlashTrak CoC utilizes purchase orders, batch and lot codes, and shipping notifications to provide end-to-end product traceability. This enables customers to meet the record-keeping requirements of government regulations by helping them to provide documentation immediately upon request. FlashTrak CoC helps food processors track and trace goods across the entire life cycle from original source to finished product throughout the supply chain. Manufacturers can also access information from third-party logistics (3PL) providers within a few hours.

Governments around the world are taking steps to protect the food supply system. In the United States, the Food and Drug Administration (FDA) enacted the Food Safety Modernization Act and in Europe, the European Commission established an integrated approach through the General Food Law Regulation to guarantee the highest level of protection of human life. All companies in a country’s food supply chain must be able to quickly trace where they received a food product and where they sent it.

FlashTrak CoC has been created to help our customers meet the requirements of government regulations and optimize operational efficiencies throughout the supply chain. Everyone involved in the food industry shares responsibility to follow food safety standards. FlashTrak CoC provides traceability recordkeeping meeting the requirements of Section 204(d) of the FDA Food Safety Modernization Act. As called out in Section 204(d), records must be maintained as either original paper record, electronic records, or true copies. FlashTrak CoC optimizes the collection and storage of these records making it efficient in meeting the requirement to respond to the FDA within the 24-hour requirement.

Complying with government regulations protects your private fleet’s brand, reduces reputational risk, and limits liability. Private fleets must use equipment that meets the government standards and shows that food products are properly handled during transit. The financial impact of failure to comply with FSMA can be crippling to a business. Likewise, noncompliance is prohibited, subject to injunction and criminal prosecution.

Built on 30 years of food industry experience and expertise, Dapicon provides an ecosystem enables seamless connection with trading partners and service providers. Data contributed by consortium partners is used for the benefit of the entire ecosystem and is used to identify, aggregate, analyze and convey results that lead to better, more informed, and faster decision making. The permission-based data sharing enables trading partners to control access to data and provides the highest level of security.

Buyers, sellers, marine traffic companies, temperature monitoring providers, government agencies, Public APIs, and logistics companies (3PLs), contribute data to the Coc. Whether supply chain participants or third-party entities, the data provided is critical to the FlashTrak Chain of Custody.

Post-harvest losses, global competition and rising consumer demand for better food quality are driving improvements in processing and packaging technologies. FlashTrak goes beyond simple track and trace of shipments, by monitoring product quality in multiple ways throughout the supply chain. Monitoring ambient air temperature only tells part of the product quality story. FlashTrak provides two methods of determining product quality based on temperature. Our internal product temperature emulation was created to monitor the temperature inside your product. Our Alpha Numeric Quality Code (ANQC) can be used to assign a shelf-life value, starting in the field. This quality indicator can be monitored through the entire supply chain, enabling you to take action to extend shelf-life.